Driving Progress Underground: The Art of TBM Execution

At Tunnel Saz Machine Co. (TSM), we are pioneers in the tunneling industry, delivering advanced technology and reliable services through our state-of-the-art Tunnel Boring Machines (TBMs). Our streamlined execution process ensures efficient project delivery, client satisfaction, and a commitment to excellence.

The execution at TSM is a meticulous blend of careful planning, precise engineering, and coordinated teamwork. Each project is customized to address unique site conditions and engineering challenges while upholding the highest standards of safety and environmental responsibility. By leveraging cutting-edge technology and innovative solutions, we empower our clients to complete complex tunneling projects on time and within budget, fostering lasting relationships built on trust and reliability.

Our systematic approach to tunneling involves several critical steps to ensure precision, efficiency, and safety at every stage:

- Project Planning and Design: Conducting detailed geological surveys, feasibility studies, and project designs to determine the optimal TBM type and tunneling strategy.

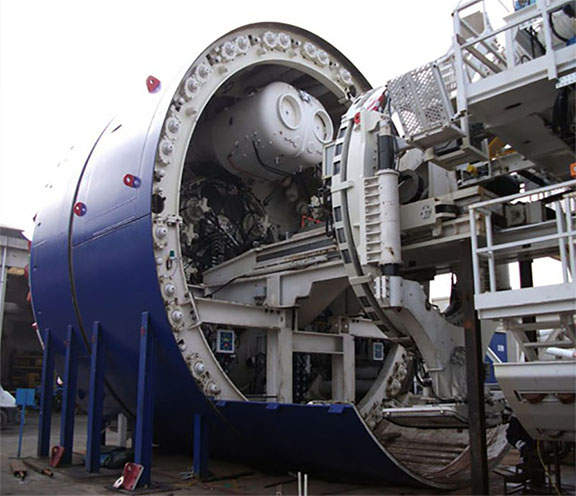

- TBM Fabrication: Manufacturing and assembling TBM components to meet the specific requirements of each project.

- Site Preparation: Preparing the launch site through excavation, setting up construction facilities, and logistics planning for smooth operations

- Launching the TBMs: Positioning and aligning the TBM with the tunnel axis while ensuring all systems are operational for the start of excavation.

- Excavation Process: Operating the TBM’s rotating cutting head to excavate soil or rock, and transporting the excavated material (muck) to the rear of the machine for removal.

- Support Installation: Installing precast concrete segments or other tunnel lining systems to ensure structural integrity during and after excavation.

- Monitoring and Control: Continuously monitoring TBM performance, geological conditions, and operational parameters to make real-time adjustments, ensuring safety and efficiency.

- Muck Removal: Removing excavated material efficiently using conveyor belts, muck cars, or other specialized systems tailored to project needs.

- Completion and Demobilization: Decommissioning the TBM, conducting thorough inspections, and performing quality checks to ensure successful tunnel completion.